Manufacturing success hinges on doing more with less, delivering higher output, greater efficiency, and deeper insight without overspending. That’s where IIoT, or the Industrial Internet of Things, makes a difference. Unlike general IoT, IIoT is built specifically for the tough demands of factory floors, providing real-time data and actionable insights that drive meaningful improvements.

IIoT isn’t just about adding new devices or boosting network speed. It creates operational bandwidth, freeing up time, resources, and decision-making power so teams can focus on what truly drives performance.

The following sections explore the core differences between IoT and IIoT, looking at how IIoT expands operational capacity in manufacturing and highlighting AI’s crucial role in maximizing IIoT’s value.

Stack up little wins to get the digital transformation ball rolling. Learn more in Impact’s webinar, Why Your Tech Rollouts Fail (and What to Do About It).

The Difference Between IIoT and IoT

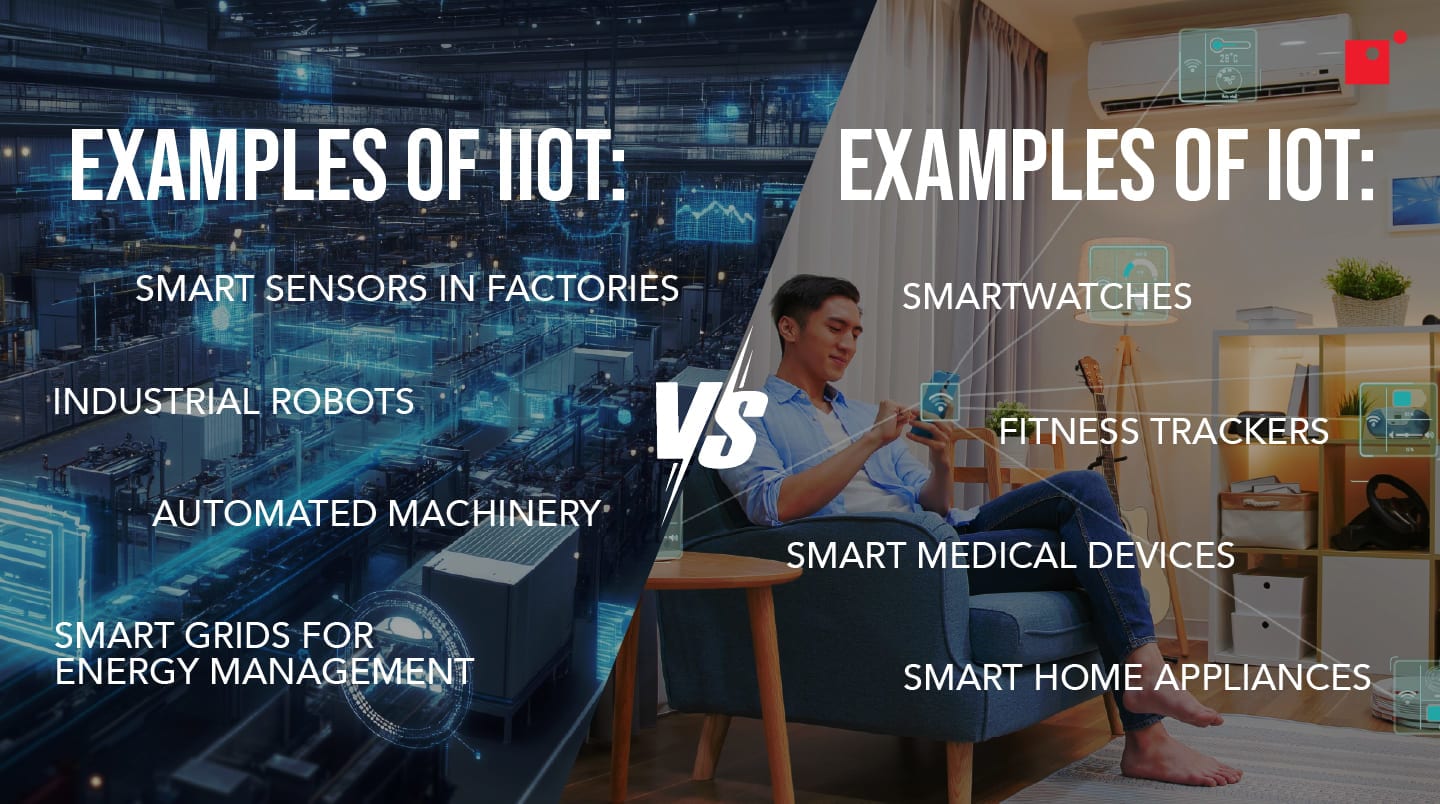

At first glance, IoT and IIoT might seem like the same thing, connected devices gathering and sharing data. But in a manufacturing environment, the differences are significant, especially when every investment needs to pull its weight.

IoT is usually associated with consumer and convenience tech. Things like smart home devices or fitness wearables. These are designed for comfort, convenience, and casual use. They prioritize ease of use over ruggedness, and they don’t have to meet the demands of a factory floor.

IIoT, on the other hand, is purpose-built for industrial settings. It’s designed to handle high-volume data streams, operate in extreme conditions, and connect deeply with operational systems. Whether it’s monitoring vibration in a motor, alerting teams to equipment anomalies, or tracking output in real time, IIoT brings precision and durability that general-purpose IoT can’t match.

This distinction matters when planning upgrades or evaluating tech investments. IIoT isn’t about fancy gadgets; it’s about giving your existing systems more visibility, control, and longevity. It’s a smarter use of resources, built to deliver ROI not just in theory, but on the floor where it counts.

Why IIoT Matters for Manufacturing

IIoT goes beyond simple connectivity; it transforms raw machine data into actionable insights that directly impact output and efficiency. In a manufacturing environment, that kind of intelligence creates ripple effects across production, maintenance, and even workforce planning.

IIoT adds value by exposing operational blind spots. Traditional systems might tell you what went wrong. IIoT shows you why, often before the problem surfaces.

Embedded sensors and edge devices stream real-time data from assets like conveyors, presses, and chillers. That data feeds into dashboards or AI models that catch performance drift, detect inefficiencies, and flag maintenance needs early enough to avoid disruption.

This level of insight prevents downtime, reduces waste, improves energy use, and helps teams prioritize limited resources. It also makes scaling more manageable. IIoT systems are modular and flexible, allowing manufacturers to start small in high-impact areas and expand as needed, without replacing everything at once.

In a cost-sensitive operation, getting more out of the equipment you already have often delivers greater returns than investing in the next big thing. IIoT enables this by turning everyday machines and processes into sources of real-time insight, efficiency gains, and measurable impact on the bottom line.

How IIoT Can Create Additional Bandwidth

When manufacturers talk about “bandwidth,” it’s not just about internet speed; it’s about capacity. Time, labor, machine availability, and mental bandwidth for decision-making. IIoT helps reclaim all of it.

By delivering real-time visibility into equipment performance, IIoT allows teams to stop reacting and start anticipating. Instead of waiting for machines to fail or operators to flag issues, systems can automatically surface bottlenecks, signal upcoming maintenance needs, and suggest adjustments on the fly.

That automation doesn’t just keep production moving; it gives your team breathing room to focus on bigger priorities.

IIoT also creates bandwidth through smarter resource allocation. When machines report their own status and performance, managers can confidently deploy people and materials where they’re needed most, avoiding overstaffing, minimizing idle time, and reducing costly guesswork.

And as data accumulates, patterns emerge. IIoT systems don’t just spot one-off issues; they reveal inefficiencies across lines, shifts, or even sites. With that intelligence, manufacturers can fine-tune processes, align output with demand, and stretch existing assets further, without burning out teams or breaking budgets.

In short, IIoT doesn’t just optimize machines, it creates space. Space to think strategically, act faster, and do more with what you already have.

Where AI Fits Into the IIoT Puzzle

IIoT generates an enormous amount of data, but data alone doesn’t drive results. That’s where AI steps in. By analyzing IIoT data at scale and in real time, AI turns raw information into focused, actionable insights that help manufacturers make smarter, faster decisions.

AI enhances pattern recognition and also boosts efficiency across the board. It can optimize production schedules based on actual machine availability, adjust energy usage during peak hours, or even recommend process tweaks to improve output—all based on live system data. That means fewer delays, tighter resource control, and faster reaction time when things change.

In the end, AI doesn’t just fit into the IIoT puzzle; it completes it. It connects the dots, clarifies what matters, and ensures the data your systems produce leads to real, measurable results.

The Business Case for Futureproofing

Futureproofing isn’t about chasing the latest tech; it’s about investing in systems that can adapt, scale, and stay competitive over time. In manufacturing, where downtime is costly and efficiency is everything, technologies like IIoT and AI offer more than short-term gains; they lay the groundwork for long-term resilience.

These tools help manufacturers respond to shifting market demands without constant disruption. Making smart technology choices today builds confidence and stability for years to come.

IIoT creates a flexible digital foundation that supports continuous improvement and makes it easier to integrate future tools without starting from scratch. AI adds agility by helping teams shift from reactive problem-solving to proactive planning, anticipating issues, streamlining resources, and responding faster to change.

Together, they unlock new levels of visibility and control across the entire operation. This means manufacturers can innovate faster while maintaining steady production.

Smart investments now reduce the risk of expensive overhauls later. By building around modular, data-driven platforms, manufacturers can upgrade gradually, stretch existing assets further, and stay ready for whatever’s next—all while keeping budgets under control. This approach also minimizes disruption to day-to-day operations, allowing teams to focus on delivering value without constant firefighting.

Wrapping Up on IIoT and IoT in Manufacturing

IIoT and AI together offer a powerful way to boost manufacturing efficiency, reduce downtime, and unlock new levels of operational flexibility. By turning machines into intelligent partners, manufacturers gain the bandwidth needed to focus on strategic priorities rather than firefighting daily issues.

This shift not only improves performance but also creates a foundation that adapts and grows alongside evolving business needs.

Making thoughtful investments in IIoT and AI builds resilience and agility, helping operations avoid costly disruptions and stay ahead of the competition. Futureproofing isn’t about chasing every new technology; it’s about choosing scalable, flexible solutions that deliver measurable results now and prepare for what comes next.

The right technology, applied thoughtfully, transforms challenges into advantages and drives lasting success.

Watch Impact’s webinar, Why Your Tech Rollouts Fail (and What to Do About It), to learn how you can start with little wins to build toward a comprehensive digital transformation in your organization.